Wholesaler vs Manufacturer: Strategies To Maximize Profits

In the world of business, understanding the roles of wholesalers and manufacturers is essential. While both play key parts in the supply chain, their functions are very different.

Manufacturers focus on creating products, turning raw materials into finished goods. Wholesalers, on the other hand, act as middlemen, buying in bulk and distributing to retailers or businesses.

Understanding the differences in wholesaler vs manufacturer roles is crucial for making informed business, retail, and supply chain decisions.

What Is A Wholesaler?

Any company or individual that buys products in bulk from producers and then resells them to retailers, other businesses, or sometimes even individual customers is known as a wholesaler.

Unlike manufacturers, wholesalers do not create or produce products; their primary function is distribution. They act as a bridge, connecting the makers of goods with the market, ensuring products reach stores and businesses efficiently.

Wholesalers often buy in bulk, which allows them to benefit from lower unit costs and provide retailers with smaller, manageable quantities, saving them from ordering directly from factories.

For instance, a clothing wholesaler purchases large volumes of shirts from a garment manufacturer and supplies them to multiple boutiques.

Similarly, a food wholesaler sources produce from farms and distributes it to grocery stores, while an electronics wholesaler buys devices from factories and delivers them to various retailers.

To ensure a smooth transition of commodities from the manufacturer to the end user, wholesalers oversee distribution, shipping, and storage.

What Is A Manufacturer?

Manufacturing is the process by which an organization turns raw resources into completed products that are prepared for distribution or sale.

They are the backbone of the supply chain, creating items that consumers and businesses rely on daily. Manufacturers can range from large-scale factories with advanced machinery to small workshops producing handcrafted items.

They design, assemble, and make sure that quality requirements are fulfilled during the entire production process. For example, a shoe manufacturer not only selects the materials but also designs, stitches, and assembles shoes to meet consumer needs.

Similarly, a phone manufacturer combines multiple components, such as screens, chips, and batteries, into a fully functional smartphone.

Furniture manufacturers turn raw wood, metal, or fabric into chairs, tables, or cabinets, ensuring both durability and aesthetic appeal.

Manufacturers are the starting point of any product journey. Without them, wholesalers, retailers, and ultimately consumers would have nothing to buy, highlighting their critical role in business and commerce.

Pros And Cons Of Wholesalers

Wholesalers are vital connectors in the supply chain. They don’t make products but specialize in buying in bulk and distributing to businesses, retailers, and sometimes customers.

At the same time, they face challenges like lower margins, dependence on manufacturers, and tough competition. Let’s look at the pros and cons in detail.

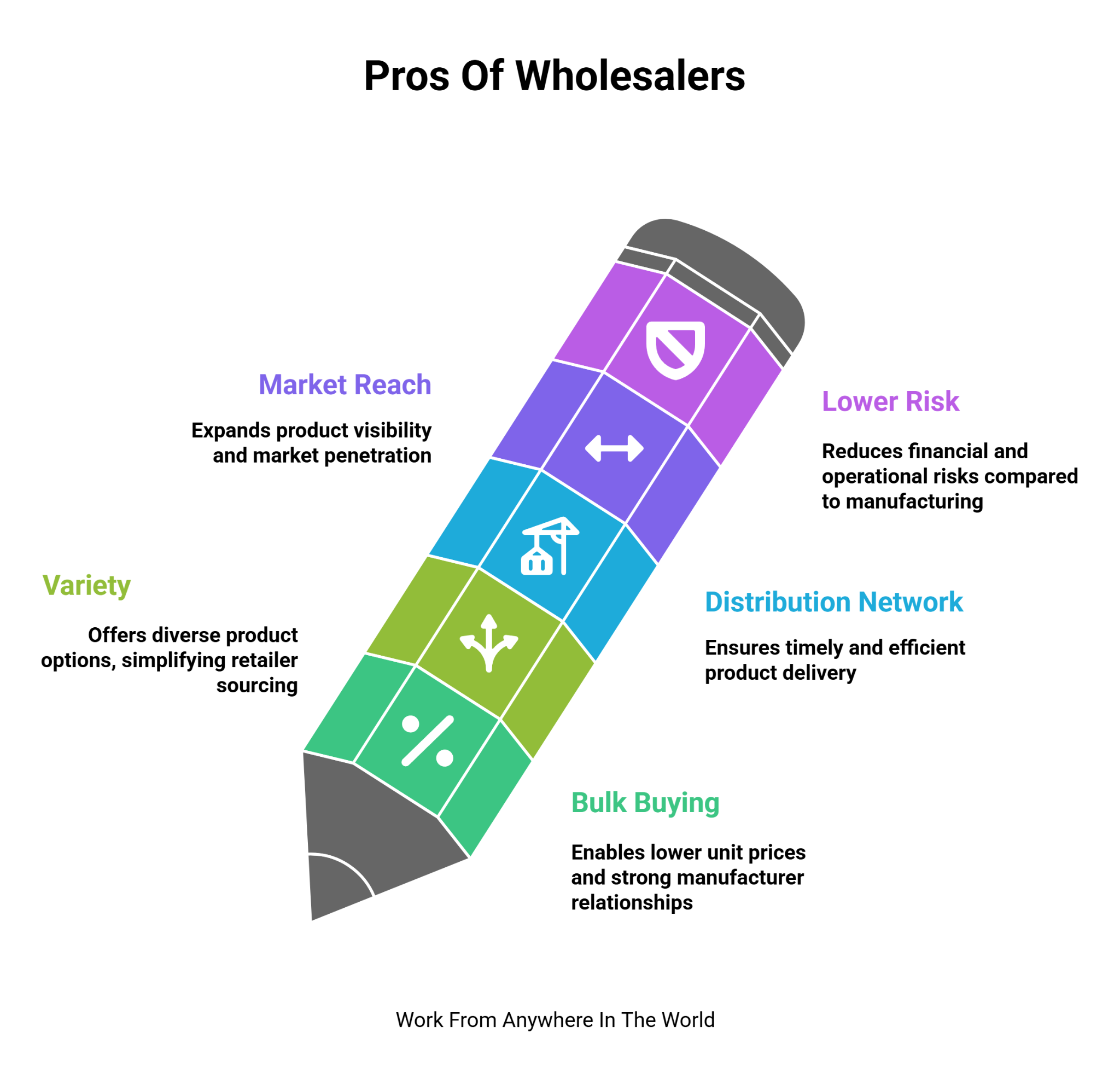

Pros Of Wholesalers

1. Bulk Buying

Large volumes of items are bought directly from manufacturers by wholesalers. They can bargain for lower unit prices because of their significant purchasing power.

The savings create opportunities to resell products at competitive rates while still making a profit. Retailers benefit because they can buy smaller quantities at manageable costs without dealing directly with large factories.

For wholesalers, this advantage creates room for consistent earnings even with tight margins. The more they buy, the better the deals they secure.

Bulk buying also builds strong relationships with manufacturers, often leading to priority supply and special pricing advantages over competitors.

2. Variety

One of the strongest benefits wholesalers offer is product variety. Instead of retailers working with multiple manufacturers, they can purchase different products from a single wholesaler.

This saves time, reduces logistics headaches, and allows businesses to offer customers more choices without maintaining large warehouses.

For example, a clothing wholesaler may stock jeans, shirts, and jackets from different factories, giving retailers a wide selection in one place.

This variety makes wholesalers valuable partners, especially for small businesses that want diverse product lines without the complexity of managing many supplier relationships. It’s convenience and cost-efficiency combined.

3. Distribution Network

Wholesalers excel in building and maintaining efficient distribution networks. They know how to move products quickly, manage warehouses, and deliver goods on time to retailers and businesses.

Many wholesalers already have established logistics systems that retailers can rely on, eliminating the need for smaller shops to manage storage and transportation.

For instance, a food wholesaler ensures fresh produce reaches grocery stores regularly, keeping shelves stocked. This network strength builds trust and loyalty among retailers who depend on timely deliveries.

Over time, a well-managed distribution network becomes the wholesaler’s biggest asset and competitive edge in the market.

4. Market Reach

Wholesalers extend the reach of products beyond what manufacturers could achieve alone. By distributing goods to multiple retailers, regions, or even countries, they

5. Lower Margins

help brands gain visibility and penetrate new markets.

This expanded market reach increases sales opportunities for manufacturers and ensures retailers have access to a wide selection of products.

Wholesalers serve as essential connectors between production and consumption, helping products move efficiently from factories to shelves.

Their understanding of networks and market dynamics allows companies to reach consumers more quickly and efficiently than manufacturers could alone.

6. Lower Risk Than Manufacturing

Compared to manufacturers, wholesalers face lower financial and operational risks. They don’t invest in raw materials, production equipment, or factory operations, which reduces capital requirements.

Their main costs are purchasing inventory, storage, and logistics. If a product fails to sell, the financial exposure is smaller than for manufacturers.

This makes wholesaling an attractive option for entrepreneurs who want to enter the supply chain without taking on the full burden of production risks.

Lower risk allows wholesalers to adapt more quickly to market changes, diversify product lines, and experiment with new offerings.

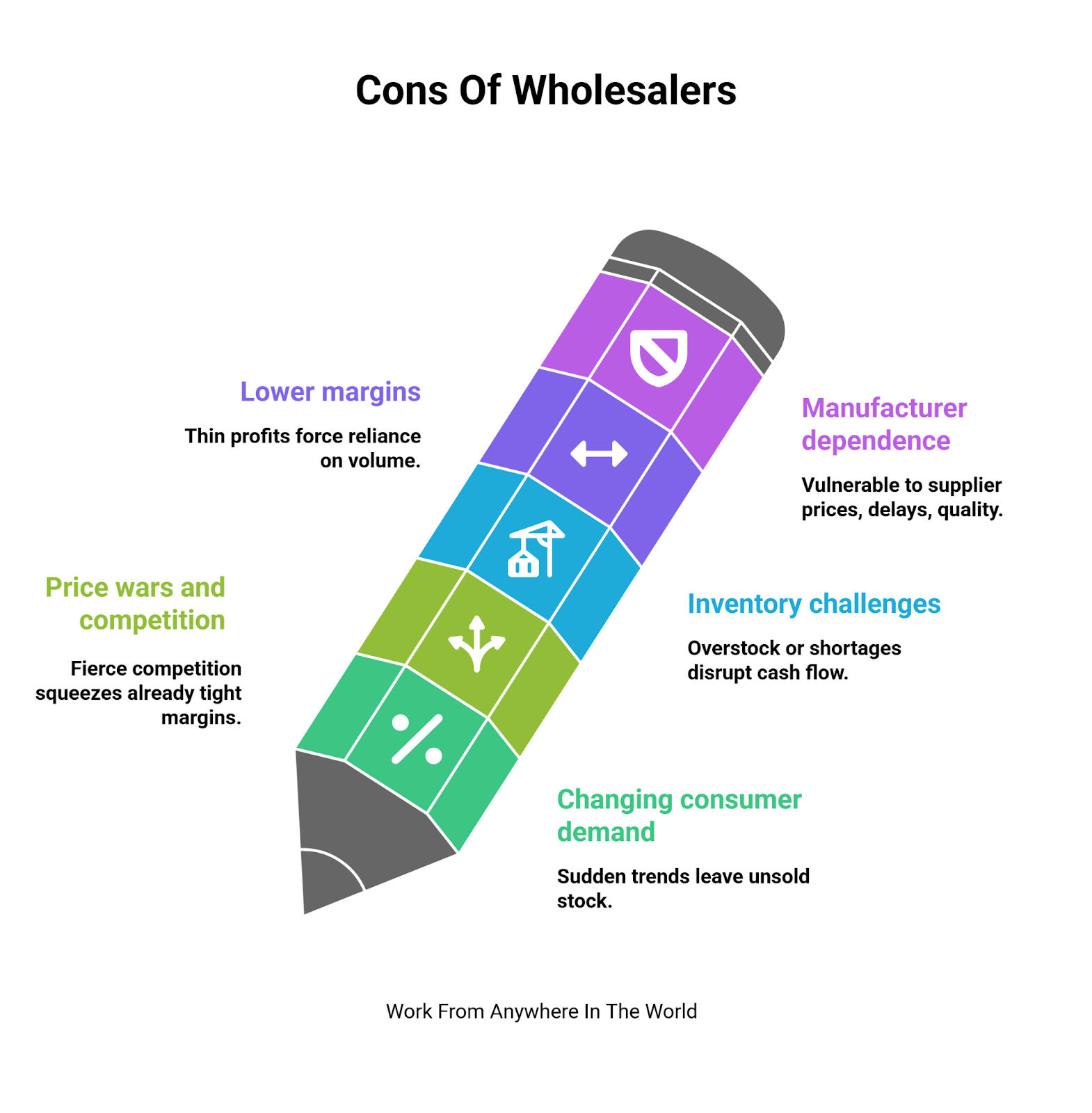

Cons Of Wholesalers

1. Lower Margins

One significant disadvantage that wholesalers face is working with thinner profit margins compared to manufacturers. Because they buy and resell without adding much value to the product itself, their earnings per unit are limited.

To remain profitable, wholesalers must rely heavily on volume sales, which can be challenging in highly competitive industries. Even small price fluctuations from manufacturers can squeeze profits further.

This means wholesalers often operate on tight budgets, where minor errors in pricing or demand forecasting can lead to losses. Lower margins force wholesalers to focus more on efficiency and high sales turnover.

2. Dependence On Manufacturers

Wholesalers rely entirely on manufacturers for supply. If a manufacturer raises prices, experiences delays, or changes product quality, the wholesaler has little control over the situation.

This dependence creates vulnerability because wholesalers cannot produce their own goods to fill gaps. For example, if a factory producing popular electronics shuts down, the wholesaler loses access to that product line.

Such disruptions can damage relationships with retailers and hurt revenue. Wholesalers must diversify their suppliers to reduce risks, but dependency on manufacturers always remains a core challenge in their business model.

3. Price Wars And Competition

Wholesaling is often a competitive game. Many wholesalers sell similar products, which can lead to constant price wars.

In trying to outdo one another, wholesalers may lower prices so much that profit margins shrink dangerously. Retailers often shop around for the cheapest option, making it hard for wholesalers to stand out purely on price.

This competition is especially fierce in industries like clothing, electronics, or food, where products are readily available from multiple sources.

To survive, wholesalers must differentiate through service, reliability, or value-added options like packaging and dropshipping support instead of just competing on price.

4. Inventory Challenges

Managing extensive inventories is a constant challenge for wholesalers. Without overstocking things that might not sell quickly, they must maintain a balance between having enough inventory to satisfy merchant demand.

Excess inventory ties up capital, incurs storage costs, and increases the risk of loss, damage, or obsolescence. Insufficient inventory, on the other hand, may lead to missed sales, delayed delivery, and stockouts.

Effective inventory management systems, accurate demand forecasting, and proper storage solutions are essential for minimizing these risks.

Wholesalers must continually monitor market trends and order patterns to ensure inventory levels match demand while maintaining cash flow and operational efficiency.

5. Changing Consumer Demand

Wholesalers are highly sensitive to shifts in consumer preferences because they rely on retailers to sell their products. Sudden changes in trends can leave them with excess stock that is difficult to move.

Unlike manufacturers, who can adjust production schedules, wholesalers cannot quickly change what they already have in inventory.

This makes forecasting and market analysis critical for their operations. Wholesalers must stay alert to emerging trends, coordinate with retailers, and adapt their purchasing strategies to avoid losses.

Failure to respond effectively can result in financial strain and impact their reputation with clients who rely on timely and relevant products.

Pros And Cons Of Manufacturers

Manufacturers play a decisive role in business because they create products directly from raw materials. Let’s break down the advantages and disadvantages in detail.

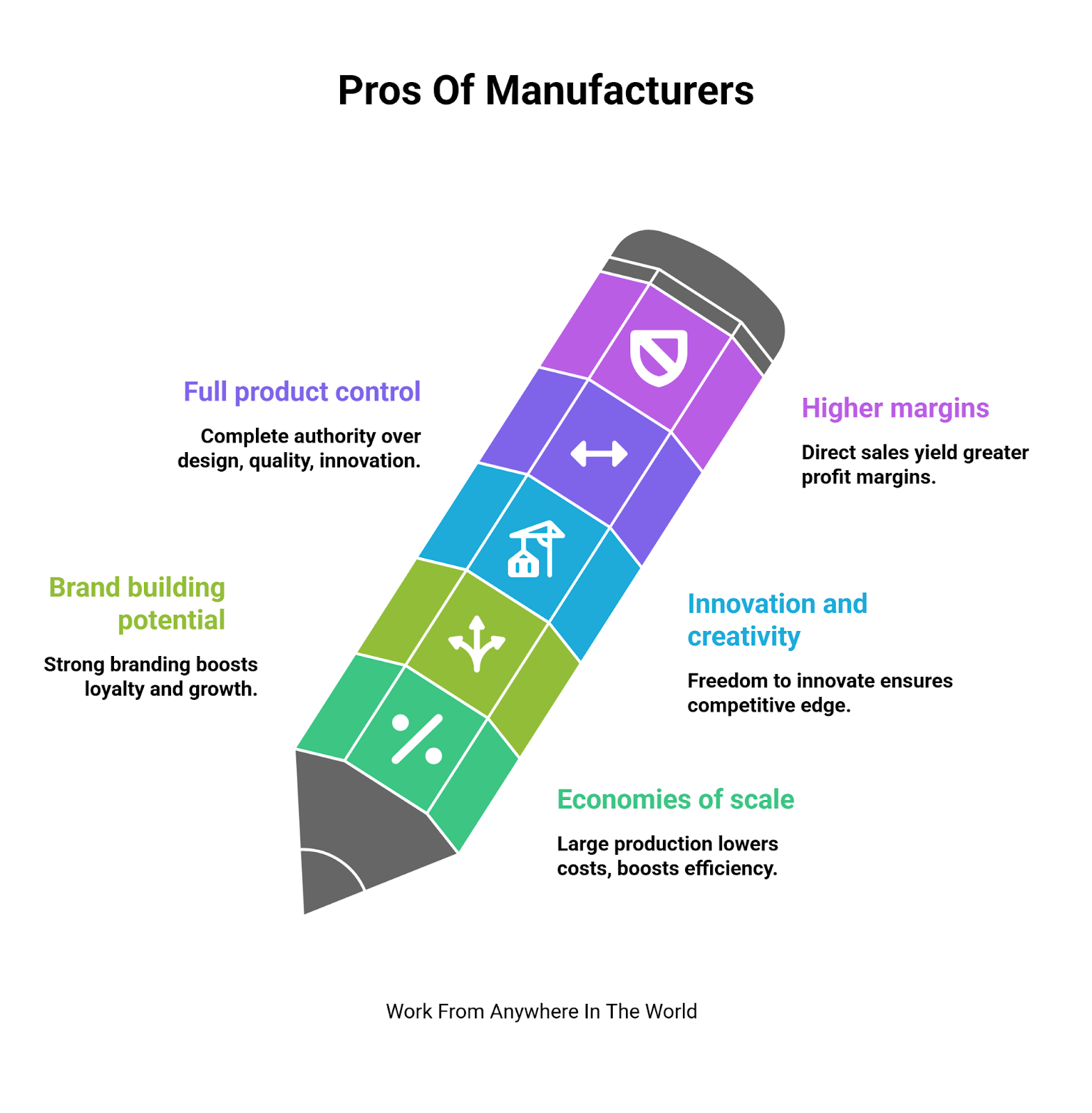

Pros Of Manufacturers

1. Full Product Control

One of the biggest strengths of being a manufacturer is having complete control over the product. From design to production, manufacturers decide how the product looks, functions, and performs in the market.

This allows for unique customization, innovation, and quality assurance. Businesses can differentiate themselves by creating signature products that stand out.

Having control also means adapting quickly to customer feedback and adjusting production methods when needed.

For example, a manufacturer can improve product design or switch materials to enhance durability and customer satisfaction. This level of control builds trust with consumers and sets the foundation for long-term success.

2. Higher Profit Margins

Manufacturers often enjoy higher profit margins because they are at the start of the supply chain. By eliminating intermediaries, they can sell directly to wholesalers, retailers, or even customers at prices that reflect both the value of the product and their production costs.

Instead of paying markups to third parties, they keep more revenue per unit sold. This is especially true for manufacturers that sell directly to consumers through eCommerce platforms.

Over time, these higher margins add up, giving manufacturers the ability to reinvest in equipment, research, and expansion. This advantage makes manufacturing attractive for long-term growth.

3. Brand Building Potential

Manufacturers have a unique advantage in building strong, recognizable brands. Since they control production and quality, they can attach their brand name directly to the goods they make.

This enables them to differentiate themselves from rivals, grow into new markets, and foster brand loyalty. Think of companies like Nike or Apple—they started as manufacturers but built global brands that customers trust.

Owning the brand means manufacturers can tell their story, connect emotionally with consumers, and charge premium prices. Over time, brand recognition becomes one of their most valuable assets, driving both sales and long-term influence.

4. Innovation And Creativity

Manufacturers benefit from the freedom to innovate and create unique products. They can experiment with new designs, materials, and production techniques to stand out in competitive markets.

This enables them to produce patents, proprietary procedures, or intellectual property while adapting to changing client needs.

Innovation drives brand value, attracts loyal customers, and often allows manufacturers to charge higher prices.

Manufacturers can implement feedback loops into production for continuous improvement, maintaining relevance and differentiation.

Creativity also encourages employee engagement, promotes a culture of problem-solving, and strengthens the company’s reputation as an industry leader in producing original and high-quality products.

5. Economies Of Scale

Large-scale manufacturers gain significant benefits from economies of scale. Producing higher volumes reduces the cost per unit, as fixed costs are spread over more items.

Bulk raw material purchases, streamlined labour, and optimized processes increase efficiency. Economies of scale allow manufacturers to price competitively while maintaining profitability.

They can invest savings into research, marketing, or expansion, further strengthening their market position. This advantage also protects manufacturers from small fluctuations in cost or demand.

Over time, achieving economies of scale creates a sustainable competitive edge, increases market share, and supports long-term growth and operational stability.

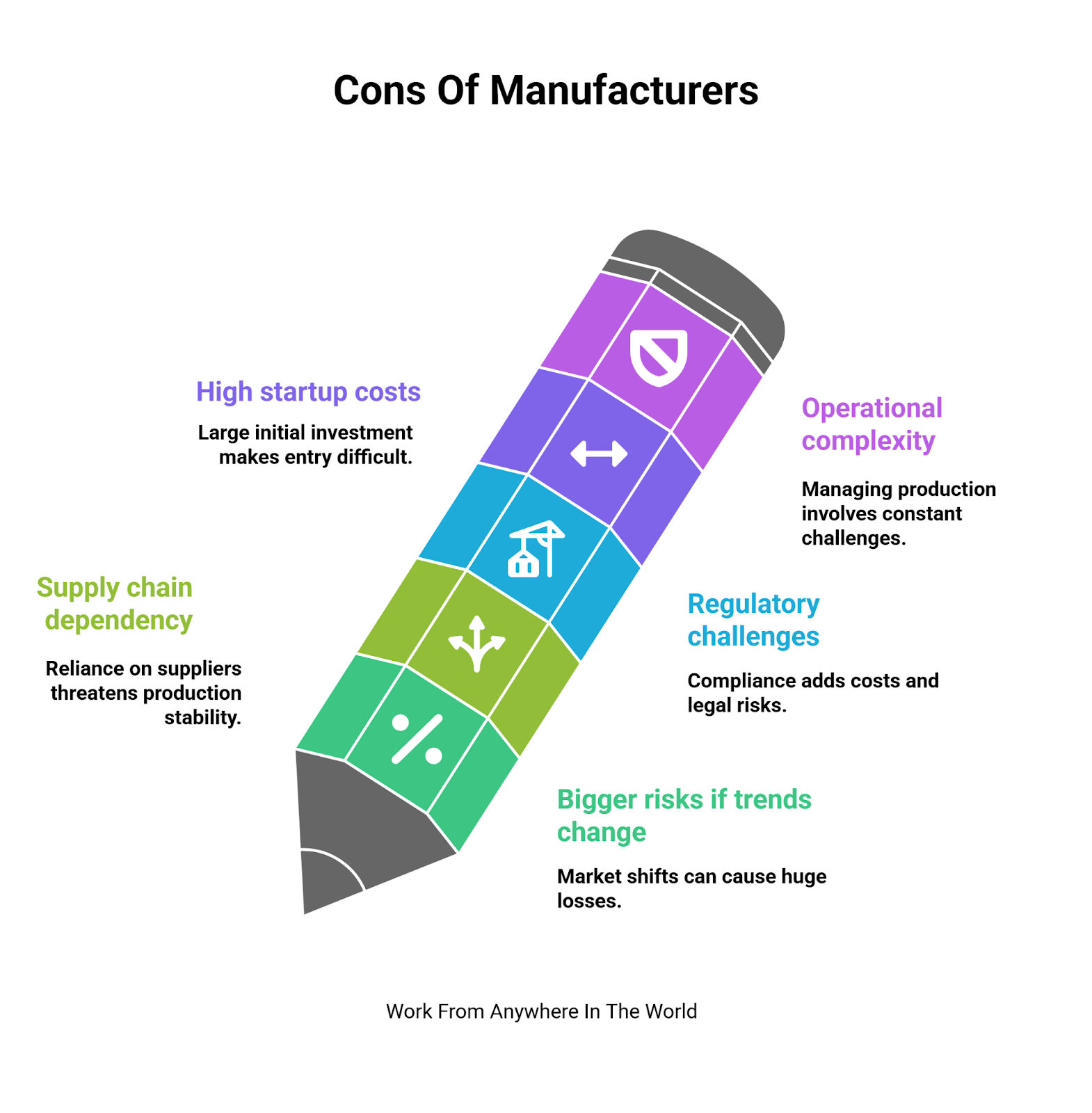

Cons Of Manufacturers

1. High Startup Costs

The biggest drawback of manufacturing is the high startup cost. Building factories, purchasing equipment, hiring skilled labour, and sourcing raw materials require significant capital.

Unlike wholesalers, who mainly handle distribution, manufacturers must invest heavily before production even begins.

This makes it harder for small businesses or beginners to enter the market. Even after setup, ongoing costs like maintenance, salaries, and energy bills can be overwhelming.

Without substantial financial backing or consistent sales, many manufacturers struggle to stay afloat. High startup costs make manufacturing a high-risk, high-reward venture that isn’t suitable for everyone.

2. Operational Complexity

Running a manufacturing business is rarely simple. It involves managing production lines, sourcing raw materials, ensuring quality control, handling logistics, and complying with regulations.

Each step requires planning, skilled workers, and reliable systems. A single issue—like a supply shortage, labour strike, or equipment breakdown—can halt production and cause significant delays.

Unlike wholesalers, manufacturers deal with both physical and technical challenges daily. To succeed, they must maintain efficiency while also adapting to new technologies and market demands.

This operational complexity makes manufacturing demanding and requires strong management skills, as well as constant investment in improvement.

3. Bigger Risks If Trends Change

Manufacturers face serious risks when market trends shift suddenly. Imagine a factory producing a product that goes out of fashion—demand drops, and unsold inventory piles up.

Because manufacturing requires large-scale production, losses can be massive if consumer preferences change overnight.

For example, a phone manufacturer may spend months building a model only to find it outdated when a competitor launches something new.

Unlike wholesalers who can adjust inventory more flexibly, manufacturers are tied to their product lines. This makes them more vulnerable to changing tastes, economic downturns, or innovations disrupting the market.

4. Regulatory Challenges

Manufacturers must comply with numerous regulations concerning labour, safety, environment, and product standards. Meeting these legal requirements can be expensive and time-consuming, often requiring specialized staff, reporting, and audits.

Fines, closures, or reputational harm to the business may follow noncompliance. Regulations may also differ across regions or countries, complicating expansion.

Manufacturers must stay updated on new laws and implement operational changes as needed. Navigating these legal obligations adds an extra layer of complexity and cost.

Maintaining reputation with clients, investors, and partners, avoiding legal problems, and ensuring product safety all depend on effective compliance.

5. Supply Chain Dependency

Even though manufacturers control production, they rely heavily on suppliers for raw materials, components, and machinery.

Disruptions in the supply chain—caused by shortages, transportation delays, political issues, or natural disasters—can halt production entirely.

This dependency introduces risk and uncertainty into operations. Manufacturers must maintain strong supplier relationships, diversify sources, and develop contingency plans to ensure consistent production.

Delays or quality issues from suppliers can damage timelines, customer satisfaction, and revenue. Maintaining profitability, reducing risks, and preserving efficiency all depend on efficient supply chain management.

Manufacturers must continuously monitor suppliers and market conditions to protect against potential disruptions.

Conclusion

In the supply chain, both manufacturers and wholesalers play essential but distinct roles. Manufacturers create and innovate products, controlling quality and building brands, while wholesalers ensure these goods reach markets efficiently, offering variety and distribution expertise.

Each has its own advantages and challenges, from profit margins to operational risks. A clear understanding of wholesaler vs manufacturer dynamics helps businesses and retailers optimize operations and maximize efficiency in the supply chain.

Ultimately, manufacturers and wholesalers complement each other, forming a partnership that keeps products moving from creation to consumers seamlessly.

I trust you enjoyed this article about Wholesaler vs Manufacturer: Strategies To Maximize Profits. Please stay tuned for more articles. Take care!

JeannetteZ

Want to Learn How to Build Your Own Home-Based Online Business And Start Making Money Online From Your Comfortable Couch?

Try Wealthy Affiliate!

Your Opinion Is Important To Me

Do you have thoughts, ideas, or questions? I would love to hear from you. Please share your questions, experiences, remarks, and suggestions about Wholesaler vs Manufacturer: Strategies To Maximize Profits in the comments below. You can also email me at Jeannette@WorkFromAnywhereInTheWorld.com.

Disclosure

This post may contain affiliate links. I earn from qualifying purchases as an Amazon Associate and through other affiliate programs. Please read my full affiliate disclosure.

You may also enjoy the following articles:

Wealthy Affiliate Coupons For Premium Memberships

Wealthy Affiliate Review – Scam or Legit? The Truth Exposed

An Insider Wealthy Affiliate Review

Integration EDI for Effortless Data Exchange and Success

Best Shopify Themes For Clothing Brands That Skyrocket Sales

Proven eCommerce Scaling Secrets To Skyrocket Your Online Sales